Made in Germany Raw diamonds

For us, "Made in Germany" is not just an indication of origin, but a promise that we fulfil day after day through reliability and the highest standards. Along the value chain, we show how we make "Made in Germany” come to life in practice. Where does ABUS produce, where are raw materials and materials sourced, what do we attach importance to? These are all key questions that we answer using some ABUS products "Made in Germany".

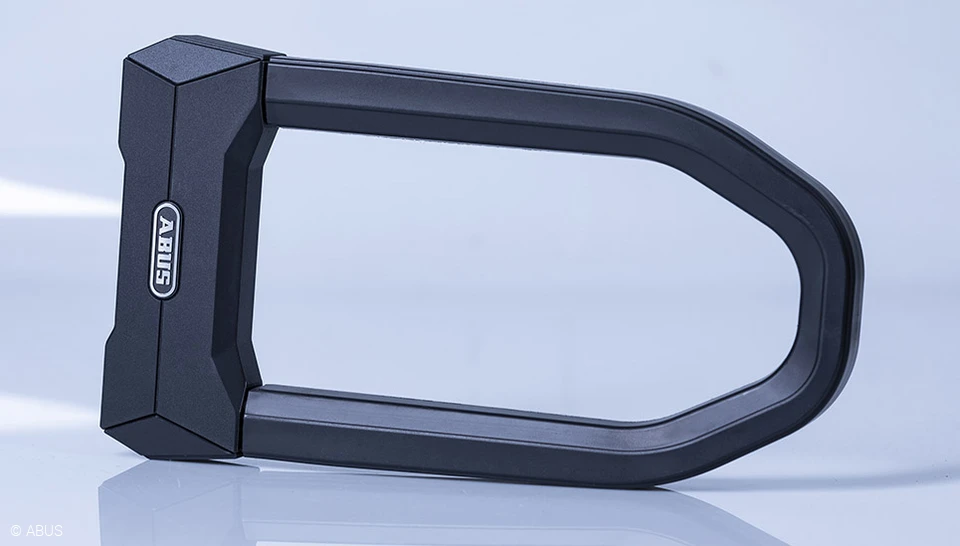

GRANIT™ SUPER EXTREME 2500 A BIKE LOCK OF SUPERLATIVES

It is ultra-resistant, tougher than ever before – and over the top? Lena Lomotowski, Product Manager at ABUS, knows that this is absolutely not the case. She was responsible for the GRANIT Super Extreme 2500 from the initial idea to the market launch.

There is a trend to which ABUS has responded. "In large cities and wherever high-quality bikes are in use, we have observed that bicycle thefts are now being committed using increasingly brutal methods, such as portable battery-powered angle grinders," explains Lena Lomotowski.

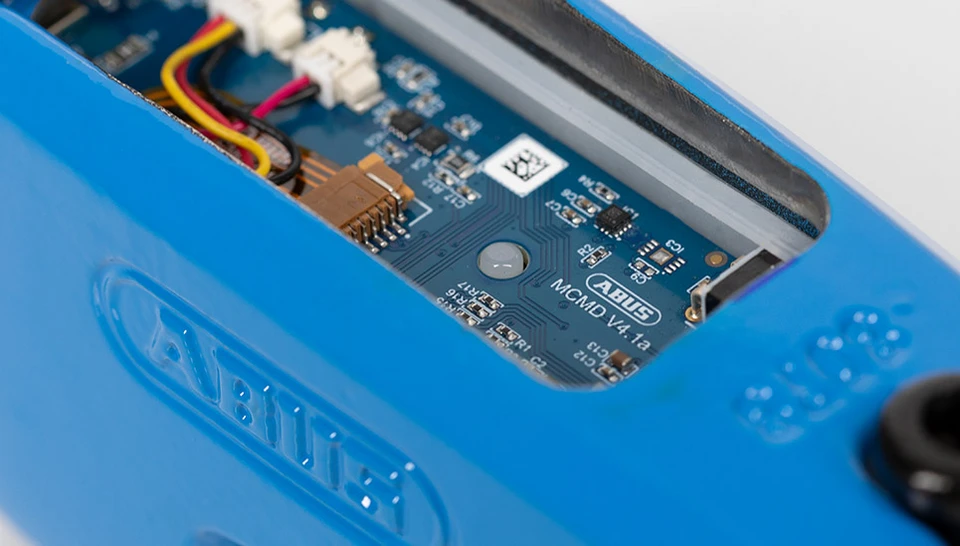

SMARTX PROTOCOL FROM TRADITION TO INNOVATION

Our 100-year tradition of supplying our customers with high-quality, reliable security has also fuelled our drive for innovation. Security has to move with the times – and it is becoming more convenient thanks to smart solutions. A core element of the digitalisation of our security products is the proprietary ABUS SmartX technology. It was developed in 2017 in the research and development centre at our production site in Rehe in Rhineland-Palatinate. This is where innovative impulses "Made in Germany" are created that change the world of security.

FOLDING LOCK BORDO 6000 DELIVERY PERFORMANCE AS A SUCCESS FACTOR

The BORDO 6000 with security level 10 is a bestseller among ABUS bike locks. But why is this product so popular with customers? With the BORDO 6000 folding lock, ABUS can offer a very high level of quality at a very fair price. The aim of the purchasing department at ABUS is also to strike a balance between price sensitivity and the high quality standards of "Made in Germany".

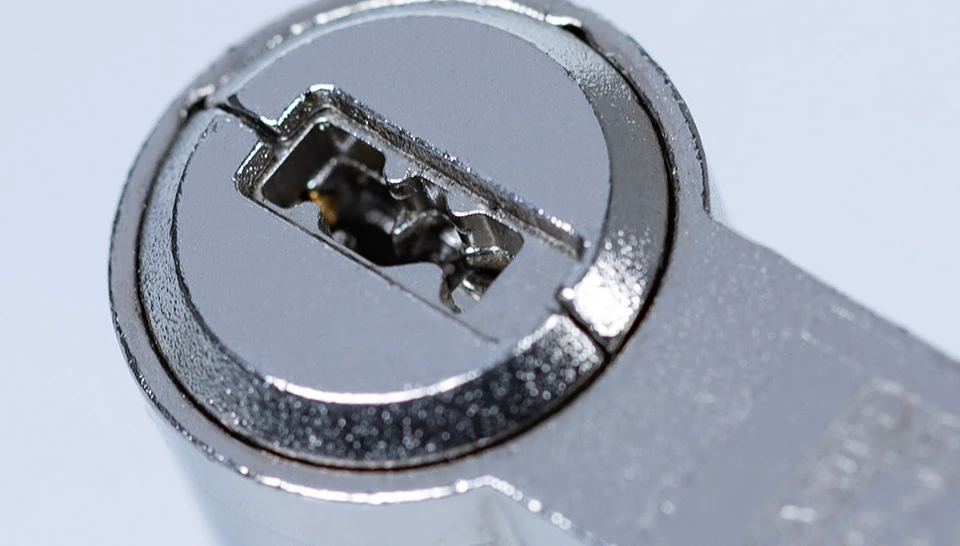

Magtec cylinder German precision with a sustainable mindset

As a specialist for key systems and with one of the most modern production facilities in Europe, ABUS has succeeded for the first time in manufacturing a climate-neutral cylinder at its Pfaffenhain production site in the Ore Mountains

With the Magtec profile cylinder, we are setting a milestone in terms of sustainability, as the housing of the profile cylinder already meets future European requirements. In addition to observing high environmental standards such as the recycling and re-utilisation of materials and resources, ABUS was already able to significantly reduce CO2 emissions during the production of Magtec and ultimately achieve climate neutrality through additional offsetting.

GRANIT™ PADLOCK THE ORIGINS

THE IRON ROCK AND THE VISION OF AUGUST BREMICKER

In 1924, the "Iron Rock" padlock marked the beginning of a long ABUS tradition in which clear production principles have always taken centre stage. Even back then, founder August Bremicker pursued the vision of creating a lock with exceptional durability and robustness. Today, this vision is the core of the product promise of our GRANIT padlocks.

DISKUS LOCK QUALITY FROM OWN HANDS

No other product epitomises the rich history and decades of experience of ABUS as much as the Diskus round shackle padlock.

Since its invention in 1949, every original Diskus has come from the hands of our experienced craftsmen in Wetter on the river Ruhr.* Using locally sourced raw materials, the finished product is created and checked in numerous steps, mainly by hand. In order to be able to guarantee the high quality of the locks at all times, the machines and tools used for production are also manufactured in-house.

*not made in Germany is the Diskus Combo 29/70